Products

D12-12PT-3

- The 1st generation of mightyZAP actuator supporting precise position control

- Cored Moter (12VDC)

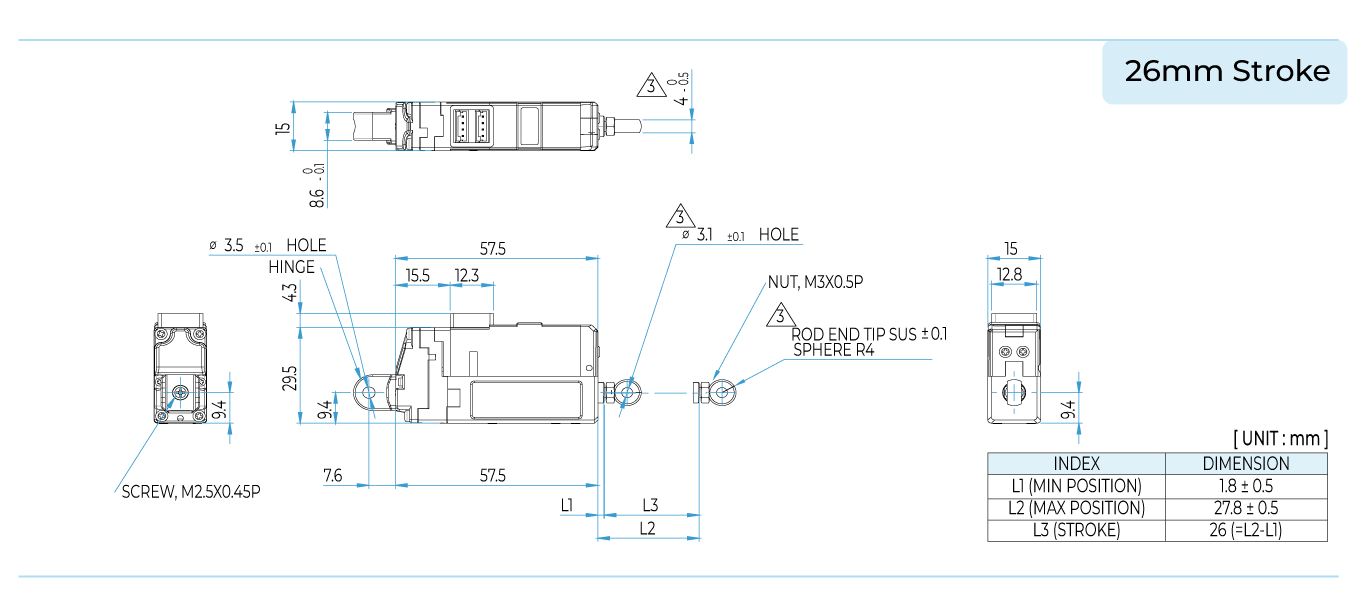

- 26mm Stroke

- Rated Load / Max Speed (No Load) : 12N / 12mm/s

- Max Allowable Load : 24N (at under 20% Duty Rate)

- Data Communication : TTL/PWM (Built-in Drive)

- Protocol : IR Robot open Protocol

- Gear Ratio 10:1

- Mechanical Self Lock (Z Axis Use) : Yes

Digital Archive

Main Features

Position Control Lineup (D12, D7 Series) Specifications

Precision

1 30μm Unidirectional repeatability

2 Absolute position sensing via Potentiometer

3 Position Feeback Available

4 32Bit Micro controller, High resolution (4096) A/D converter

Durability

1 Cored DC motor applied

2 Smart Overload protection detects jam or over 50% duty-rate (Overridable)

3 Life-cycle Reference Data is on our website (Under 50% duty cycle recommended)

4 Vertical (Z axis) use is possible thanks to mechanical Self-lock

(Certain models are not applicable, see the model specification chart)

Easiness

1 Compact size for space constraints

2 Hassle-free, Built-in drive circuit

3 Daisy chain serial connection between actuators

4 Various mounting solutions

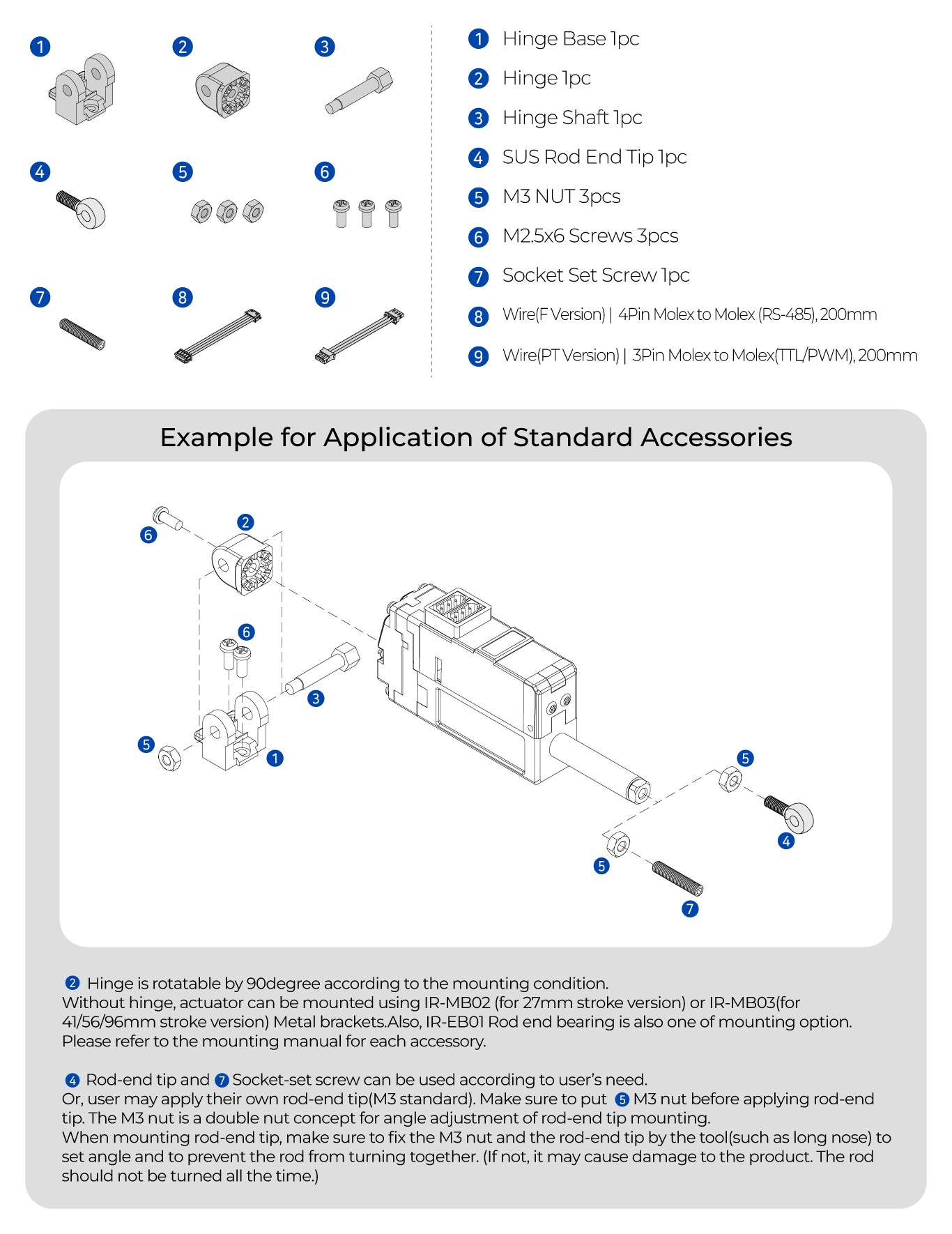

5 Detachable and 90° rotatable hinge design (Patented)

6 Various APIs / Libraries / Examples of programming languages

(C# / C++ / Python / LabView / Java / Raspberry Pi / Arduino etc.)

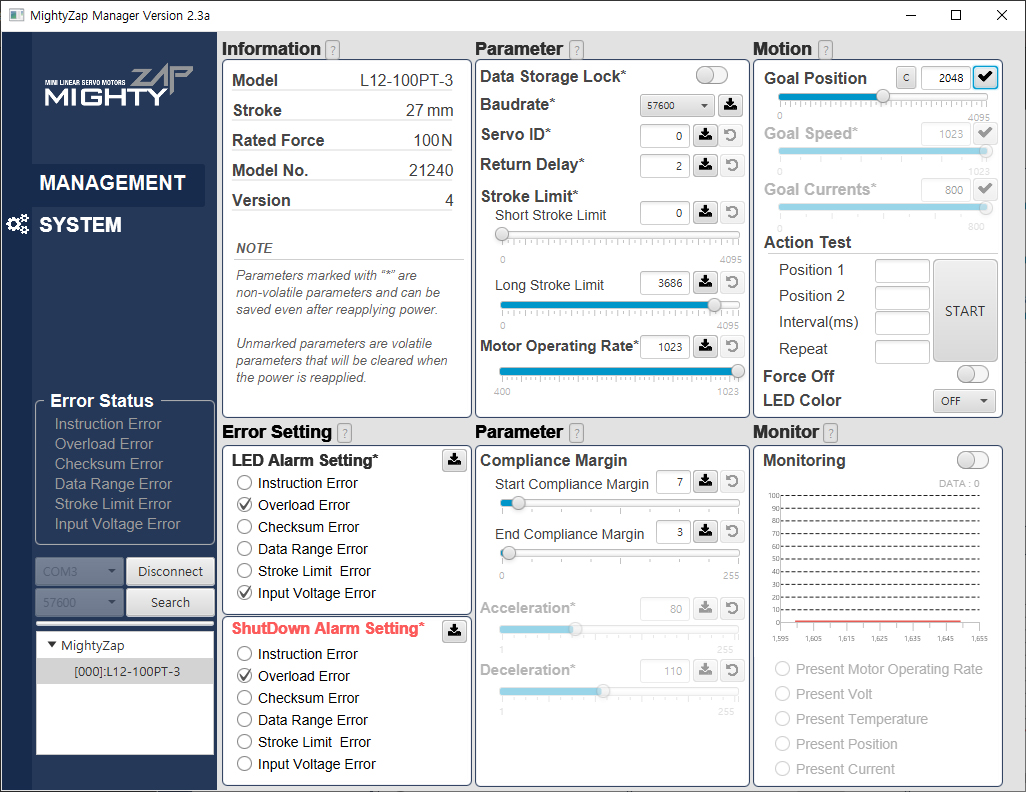

7 Dedicated PC Software (Parameter setting & simple motion testing) and PC USB Interface (IR-USB02) available (Optional)

8 LED Error indicator & LED self-diagnosis function

9 Paired with various controller types (PC / PLC / Arduino / Rasberry-Pi / RC Controller / Dedicated embedded board etc.)

Variety

1 Rated Load options (6, 12N)

2 Speed options (12mm/s, 36mm/s at No load condition)

3 Two types of data communication options (TTL or RS-485)

4 IR open protocol (refer to the user manual)

5 TTL(Data comm.) or PWM(Pulse signal) is automatically recognized in TTL/PWM version

6 Customization is actively available

Applications

1 Medical device and Lab equipment

2 Kiosk machines

3 Robotics

4 Automation (Factory / Home / Agriculture etc)

5 Production and inspection jigs

6 UAV (Fixed wing / Helicopter / Multicopter etc)

DYI, Education, Hobby, etc

Common Specifications

| Repeatability | Stroke | Unidirectional | ||||

|---|---|---|---|---|---|---|

| 26mm | 30μm (0.03mm) | |||||

| Mechanical Backlash | 0.03mm (30μm) | |||||

| Gear Ratio | 10:01 | |||||

| Gear Type | Engineering Plastic Gears | |||||

| Rod Type | Engineering Plastic Rod | |||||

| Motor Type | Cored Motor | |||||

| Motor Watt | 4.2W | |||||

| Recommended Duty Cycle | At Rated Load | At Max Applicable Load | ||||

| Max 50% | Max 20% | |||||

| Position Sensor | 10KΩ linear Potentiometer | |||||

| Input Voltage Range | 12V lineup : 7~13V (Rated : 12V) / 7.4V lineup : 6.5~8.9V(Rated 7.4V) | |||||

| Current Consumption | 7.4V Lineup | 12V Lineup | ||||

| Idle | Rated | Stall | Idle | Rated | Stall | |

| 30mA | 250mA | 0.48A | 30mA | 140mA | 0.3A | |

| Audible Noise | Approx. 50db at 1m | |||||

| Data Communication / Protocol | RS-485 or TTL(PT version) / IR Robot open protocol | |||||

| LED Indication | Two Errors Indications (Input voltage, Overload) | |||||

| Pulse Signal / Pulse Range | PWM (PT version, R/C Hobby Signal) / 900μs(Retracted)-1500μs(Center)-2100μs (Extended) | |||||

| Ingress Protection | IP-54 (Dust & Water Tight) | |||||

| Size / Weight (Excluding rod-end & hinge) | 57.4(L)x29.9(W)x15(H)mm / 49~52g | |||||

| Operating Temperature | -10℃ ~ 60℃ | |||||

| Wire Harness | TTL(PT version) : Molex to Molex Type | |||||

| (Molex 50-37-5033, 3pins) / 200mm length, 0.08×60(22AWG) | ||||||

| or RS485(F version) : Molex to Molex Type (Molex 0510650400, 4pins) / 200mm length, 0.08×60(22AWG) | ||||||

Dimension

Standard Accessories

mightyZAP Manager SOFTWARE